1. Three groups with 6S management standard, handing down the projects clearly everyday.

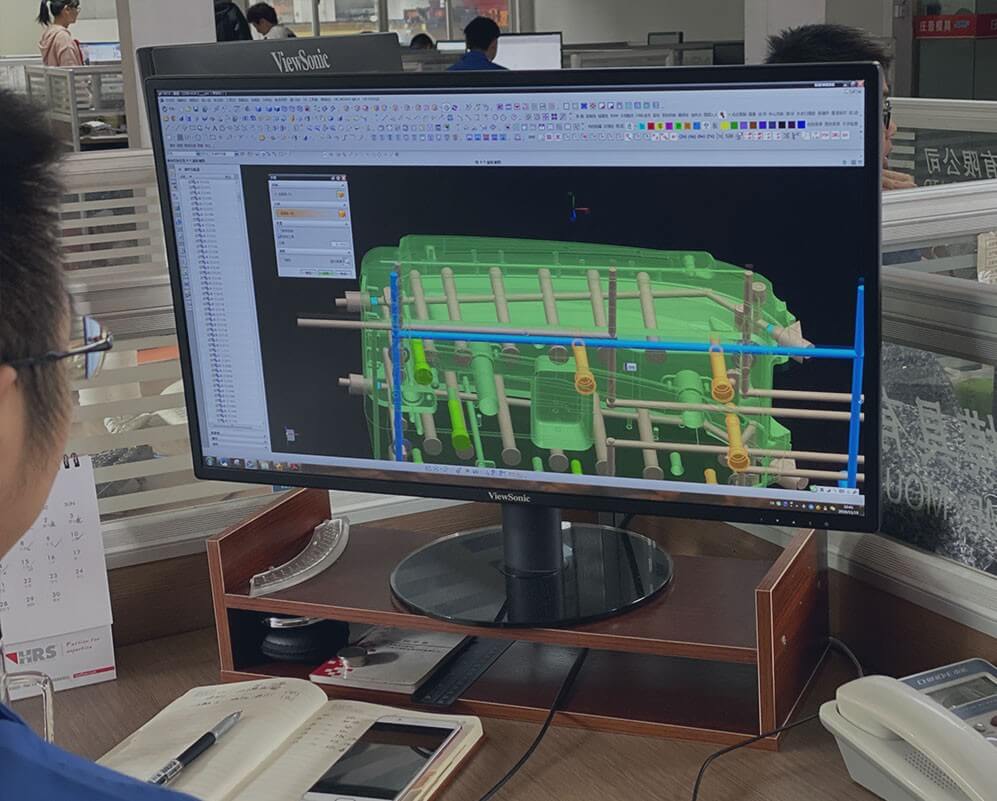

2. With company costomized design standard, giving the mould design higher speed and stronger quality.

3. Six-teen years design data collecting, construting the most powerful footstone.

4. Communicating and transforming data with professional and secure tools, gurantee the work efficiency and data security.

5. Every employee with fixed part to build up the strong design assemble line.

Based on the 3D product data provided by the customer, in accordance with the customer's various standards for the purpose of high quality, low cost, excellent technology, and strong structure.

At present, the company's quality management system has passed the certification of ISO9001: 2015, IATF16949 and VDA6.4 and other system standards. The quality management system is fully extended to the company's various levels with the quality assurance department as the center.

Monitor the quality of the mould process and the inspection before the mould test. Supported by rich and effective measuring equipment resources and human resources, control every size and problem of the mould to ensure that the mould shipment rate is 100%.

Participate in supporting customer's product design, and conduct feasibility analysis of product and mould structure, remove problems in the early stage, save time and cost and improve quality for mould design and processing.

Raw material monitoring is a crucial step in quality control. Controlling the inflow of unqualified raw materials can avoid the quality problems of the mould itself from the source, and strictly control the quality of all kinds of mould raw materials to the factory for acceptance.

According to the customer's 3D product data and mould structure data, the product production moulding process parameter simulation is conducted, the product structure and mould structure design are guided, the practical injection moulding parameters are provided for mould production, the production efficiency is reduced, and the number of debugging is improved.

At the same time, combined with the on-site summary to improve the mould flow analysis parameters, provide the process report closer to the actual production.